Food & Beverage Analysis

Ensuring strict quality control and meeting regulatory standards in the food and beverage industry can be challenging. Balancing the need for precision and reliability while keeping up with throughput demands creates a challenging atmosphere for analysts utilizing manual or inefficient methods. Reliable automated analyzers and sample preparation systems relieve the stress put on analysts, providing valuable time to give attention to the details that matter most.

.jpg?resolution=1400x650&quality=95)

Proven Tools for Efficient Food and Beverage Analysis

From robotic sample preparation systems to sample analysis, SEAL Analytical offers a suite of automated solutions to help your lab grow and keep up with demand. Our continuous flow analyzers provide reliable automation of colorimetric methods with low detection limits and the capability to complete runs and shut themselves down entirely unattended. The DEENA automated digestion block ensures each sample is treated identically, taking samples through the entire digestion process from reagent-addition and mixing, to heating, and even filling to volume or diluting post-digestion. Take your automated sample prep even further with our robotic platforms for automated sample filtration, dosing, dilution, mixing, pH, and more.

Nitrate and Nitrite Analysis in Milk and Dairy Products

SEAL Analytical provides automated solutions for nitrate and nitrite testing in milk and dairy products, following ISO 14673-2:2004 standards. Using the standard nitrate/nitrite colorimetric reaction, nitrite couples with sulphanilamide and NEDD to form a purple azo dye, while nitrate is first reduced to nitrite via a copperized cadmium reductor before undergoing the same reaction. Both nitrate and nitrite are detected at 540 nm. Dialyzers separate the analyte from the sample matrix, allowing analysis of various dairy products, including liquid milk, milk powder, whey powder, and infant formula. While most liquid samples require minimal preparation, high-fat products like cheese and gelatine may need additional processing to prevent interference with the dialyzer. SEAL offers both high-throughput automated systems and compact analyzers to meet a range of laboratory needs.

.jpg?type=webp&quality=85&background=ffffff7f&force_jpg_crop=1&resolution=1920x1600)

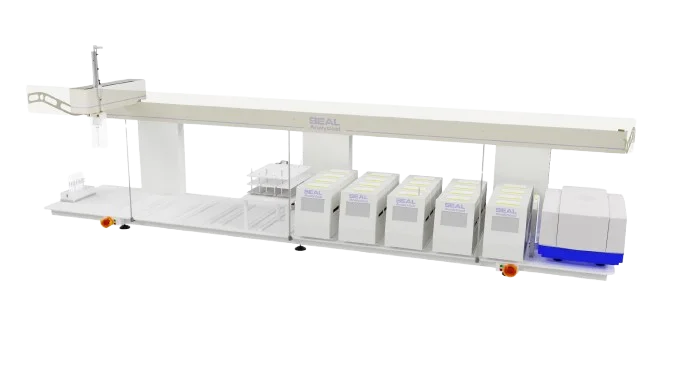

Automating Solid Fat Content Analysis with the MiniLab

The SFC MiniLab is an advanced robotic system designed for the efficient and precise handling of Solid Fat Content (SFC) analyses, including ISO 8292-1 and ISO 8292-2 for the analysis of animal and vegetable fats and oils.

Engineered for high throughput and accuracy, this robot automates the preparation and processing of SFC samples with STU blocks which reduces manual intervention and increases laboratory efficiency. With a robust design and advanced features, it supports seamless integration with your existing lab infrastructure.

Common Methods for Food & Beverage Analysis

With over 1,000 methods developed, we offer many applications for the food and beverage market. Which each lab’s needs being unique, we have only listed our most common applications here. If you are looking for a specific application, please contact our sales team. Select a specific analyzer to discover more information including ranges and method references.

.png?resolution=160x128&quality=95)

.jpg?resolution=428x267&quality=95)

.png?resolution=428x267&quality=95)