DEENA 3 Automated Digestion System (Legacy System)

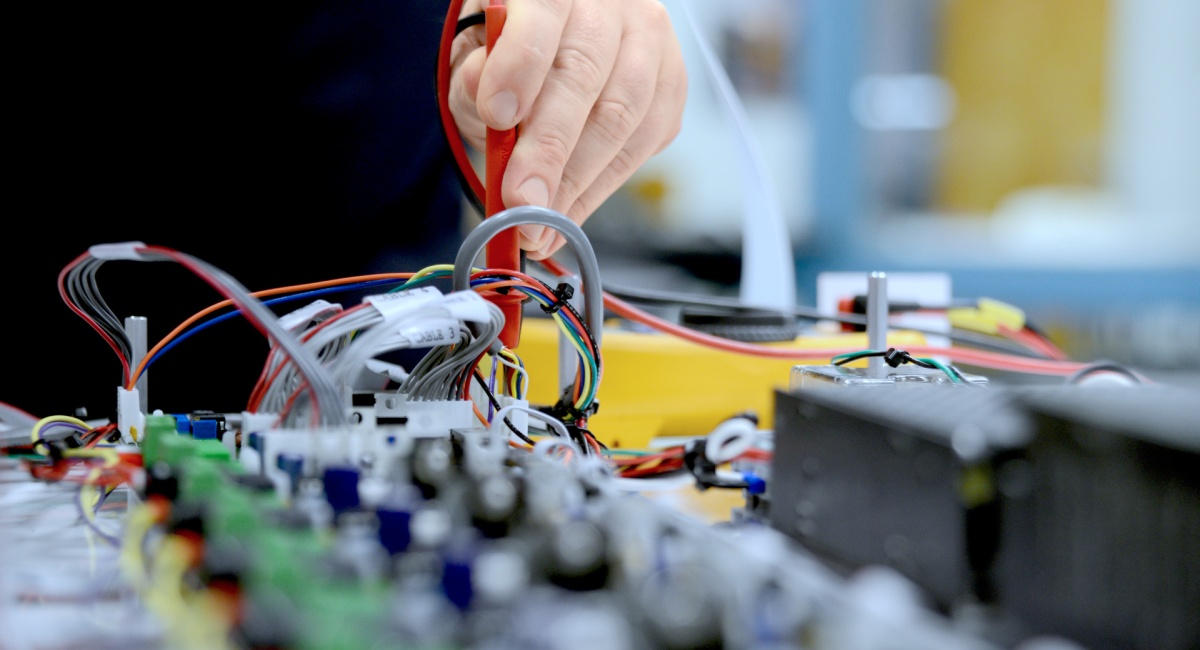

Predecessors to the DEENA 4, the DEENA 3 increased the capacity of previous DEENA systems and introduced dedicated reagent pumps for precision dispensing. Like other DEENA systems, the DEENA 3 fully automates digestion and sample prep processes including accurate dispense of reagents into sample tubes, mixing, heating, and reconstituting to a precise final volume after the digestion.

(1).png?resolution=325x0&quality-95&trim=1)

An Expansion to the Original DEENA Lineup

The DEENA 3 is an automated digestion block widely utilized for metals and mercury digestions, automating the digestion process with precise reagent addition, thorough sample mixing, heating to programmed temperatures, and reconstitution of the sample post-digestion. Although no longer manufactured or sold after the release of the DEENA 4, this legacy system remains fully supported by SEAL’s service teams, reflecting our longstanding commitment to laboratory automation and optimized trace metals analysis. By eliminating manual acid handling and delivering exact reagent dispensing, the DEENA 3 reduces human error commonly introduced in the digestion step and ensures highly reproducible results for environmental and analytical labs alike. With durable construction, a compact footprint, and advanced features like overnight runs, stand-by warming, and fill-to-volume functionality, DEENA 3 continues to be a trusted solution for those seeking to streamline their metals and mercury digestion workflows.

The Next Step in Advanced Metals and Mercury Digestion

Released in 2018, the DEENA 3 further extended the legacy of SEAL Analytical’s original DEENA and DEENA II systems, providing an ideal solution for laboratories seeking to automate or optimize metals and mercury digestions. By expanding capacity to 72 positions for standard 50 mL digestion tubes, the DEENA 3 enabled higher throughput and improved efficiency in trace metals analysis. It also introduced a higher maximum digestion temperature, allowing laboratories to automate a broader range of acid-handling protocols for heavy metals testing and environmental compliance.

One of the most significant upgrades to the DEENA 3 was the switch to individually calibrated peristaltic pumps for up to 12 different reagents. This new approach accounts for each reagent’s unique viscosity, minimizing cross-contamination and enhancing dosage accuracy for methods that require multiple reagents. Earlier DEENA models relied on a single peristaltic pump with an 8-way valve—sufficient for many labs, but less flexible for complex workflows. Now, the DEENA 4 incorporates both dispensing options, offering the traditional 8-way valve configuration as well as optional dedicated peristaltic pumps to accommodate a wide range of digestion procedures and preferences. These improvements reflect SEAL Analytical’s ongoing commitment to developing robust solutions that meet the needs of real analysts and laboratories.

Continued Support & Transition to Modern Systems

Whether you’re maintaining an existing DEENA or considering an upgrade to a newer system, SEAL Analytical’s team stands ready to assist. Reach out to our experts for personalized guidance, support, and advice on transitioning your methods and workflows to modern instrumentation.

Ongoing Support for Legacy Systems

All DEENA models are still fully supported by SEAL Analytical. We continue to offer consumables and spare parts as well as service and technical assistance from our support chemists and technicians. Our expert teams provide remote troubleshooting, on-site service visits, and factory repairs. Keep your system running smoothly, contact us today for assistance!

(4).jpg?resolution=1200x650&quality=95)

Meet the DEENA 4: The Next Generation

The DEENA II and DEENA 3 serve as the foundation for SEAL Analytical’s DEENA 4. This latest iteration continues the legacy of innovation, combining years of expertise and customer feedback to deliver an unparalleled system adaptable to the unique needs of different industries. With improved mechanical alignment, options for an 8-way valve pump and dedicated individual pumps, syringe module for sample spiking, modernized and intuitive software, sample tube sensors, and more - the DEENA 4 introduces new ways of optimizing your automation procedures.

DEENA Automated Digestion Block Methods

The DEENA can be programmed to meet your lab’s digestion needs to prep samples for a wide-range of methods. The system is commonly used for digestion before a variety of analyses including metals and mercury analysis. Contact our team for more details on what your DEENA can do for your lab!

| EPA Method Number | EPA Method Name |

| 3005 | Acid Digestion of Waters for Total Recoverable or Dissolved Metals for Analysis by Flame Atomic Absorption (FLAA) or Inductively Coupled Plasma (ICP) Spectroscopy |

| 3010 | Acid Digestion of Aqueous Samples and Extracts for Total Metals for Analysis by Flame Atomic Absorption (FLAA) or Inductively Coupled Plasma (ICP) Spectroscopy |

| 3050A | Acid Digestion of Sediments, Sludges, and Soils |

| 3050B | Acid Digestion of Sediments, Sludges, and Soils |

| 200.2 | Sample Preparation Procedure for Spectrochemical Determination of Total Recoverable Elements |

| 200.7 | Determination of Metals and Trace Elements in Water and Wastes by Inductively Coupled Plasma-Atomic Emission Spectrometry |

| 200.8 | Determination of Trace Elements in Waters and Wastes by Inductively Coupled Plasma-Mass Spectrometry |

| 7470A | Mercury in Liquid Waste (Cold-Vapor Technique) |

| 7471A | Mercury in Soild or Semisolid Waste (Cold-Vapor Technique) |

| 245.1 | Determination of Mercury in Water by Cold Vapor Atomic Absorption Spectrometry |

| 1631 | Mercury in Water by Oxidation, Purge and Trap, and Cold Vapor Atomic Fluorescence Spectrometry |

| 245.7 | Mercury in Water by Cold Vapor Atomic Fluorescence Spectrometry |

Other models

Frequently Asked Questions

Below, we’ve listed a few frequently asked questions that will help you better understand our Digestion Systems. If you don’t find the answer you're looking for, please don't hesitate to contact our support team for further assistance.

As the digestion block simply follows the programmed steps based on your already approved digestion method, they typically do not require a separate approval to automate an existing approved method.

During any metals digestion, contamination is a concern. The DEENA 4 automated digestion system for trace metals digestion is built with a metal-free digestion zone to minimize the potential for metals contamination. The system utilizes a glass top, PTFE upper housing, and carbon fiber construction for the dispensing arm, along with a graphite digestion block. We take additional contamination-eliminating steps by requiring proper ventilation, removing fumes during the digestion.

The DEENA requires 80 CFM of airflow ventilation if placed in a fume hood. SEAL offers a stand-alone fume hood attachment that connects directly to the top of the DEENA to integrate with existing duct work, which allows for the flexibility to place the DEENA anywhere in the lab, freeing up valuable fume hood space. This stand-alone fume hood is sealed with a foam gasket and HEPA filtration.

Ready to get started on your next digestion system?

Request Information

Fill out the form below to request information about our products and services.

(1).png?resolution=290x200&quality=95)

.png?resolution=290x200&quality=95)