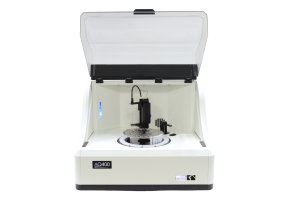

AQ700 Discrete Analyzer

The highest capacity and throughput offered in a discrete analyzer. Designed by chemists, for chemists.

(1).png?resolution=325x0&quality-95&trim=1)

Product Overview

The SEAL AQ700 discrete analyzer for nutrient analysis is engineered specifically to meet the needs of the highest-throughput environmental laboratories. It was designed in collaboration with these lab, ensuring the wide-spread needs for automation, hardware, and software were met. It is ideal for applications that require a wide range of chemistries, limits of detection that ensure compliance with regulatory requirements and seamless integration with LIMS.

Four robotic arms and four sample trays utilize automated colorimetric reactions to facilitate fast, precise, and reproducible results. Combining a high level of automation, including QR code sample scanning, with high-capacity performance and long walkaway times for unattended operation, the AQ700 is a proven tool for taking nutrient analysis to a whole new level of efficiency.

View the full specifications

Download the brochureWhy select the AQ700?

Automation

- True unattended operation with the ability to run overnight

- Integrated barcode scanning for samples and reagents

- Automated standard preparation and dilution of over-range samples

- True automated sample blanking for background color correction

- Automated sample spiking

Compliance

- No carryover or cross-contamination

- Standard 10 mm quartz cuvette

- Lower detection limits

- Chemical reaction brought to full completion emulating manual and segmented flow methods

Efficiency

- Ultra-low reagent consumption

- Ability to add samples after the run has started

- Advanced robotics for faster sample preparation per hour

- Easy maintenance & easy-change syringe

Support

- Visual manuals and descriptive checklists

- Immediate support available from SEAL chemists via email, phone, screenshare, or video call

- In-depth training during installation

- Guides and webinars available for continued learning

Highlights of the AQ700

.png?resolution=595x500&quality=95)

.jpg?resolution=595x500&quality=95)

.jpg?resolution=595x500&quality=95)

.jpg?resolution=595x500&quality=95)

.jpg?resolution=595x500&quality=95)

.jpg?resolution=595x500&quality=95)

.jpg?resolution=595x500&quality=95)

Find the highest throughput and capacity with two sampling arms, increased motor speed, and four on-board sample trays automatically handled by a robotic arm.

With built-in barcode scanners for reagents and samples, the AQ700 automates not just the test, but also data entry and handling, providing even more automation for busy laboratories. AQ software for SEAL discrete analyzers also offers flexible import and export options for full compatibility with LIMS.

An optically pure quartz cuvette provides a 10mm pathlength for maximum sensitivity and lower detection limits. Quartz is superior to styrene for sample analysis, ensuring excellent precision.

SEAL discrete analyzers use just 20 - 400 μL of reagent per test, lowering reagent costs and consumption as well as potential hazardous waste. On-board reagent cooling keeps reagents fresh through long testing periods, and built-in reagent level sensors ensure sufficient volumes for the tests before the run starts. Expiration dates are tracked in the software to remind analysts when it’s time to remake a solution.

With detection taking place in a 10 mm flow-through quartz cuvette rather than in reaction wells, consumable costs are significantly lowered as reaction wells are not used in the optical read. Constant heating and a programmable reaction time ensure reactions reach completion before transfer from the reaction well to the cuvette.

All SEAL discrete analyzers can run all types of nitrate reduction for colorimetric analysis of nitrate. Our most popular method is cadmium reduction due to the low cost and ability to handle a wide-range of sample types including wastewater, drinking water, industrial, and seawater samples. With cadmium reduction, all hazardous waste is contained in solid form in the cadmium coil for easier, safer disposal, rather than liquid form in other reduction methods. The cadmium coil can be regenerated in-line automatically, saving valuable analyst time.

A feature unique to SEAL discrete analyzers, our probe washer moves with the sample probes wiping the probe clean before moving to a new location, eliminating cross-contamination of samples, reagents, and diluents.

Coming Soon: Pre-Made Reagents for SEAL Discrete Analyzers!

SEAL Analytical has partnered with Inorganic Ventures to offer high-quality, pre-made reagents specifically designed for our discrete analyzers. Enhance productivity, accuracy, and stability in your EPA-approved water and soil testing—while significantly reducing prep time.

How the AQ700 Works

Step 1

Samples and reagents are loaded, system is started

An analyst loads one of the four onboard sample trays with samples. The system is started and the assigned sample tray is automatically moved into the testing tray position and analysis begins. The additional three sample trays can now be filled and added into the testing queue to be analyzed when the first tray is complete.

Step 2

Optional barcode scanning

If desired, sample and reagent barcodes are scanned by the AQ700 to read sample IDs, tests, manual or auto dilutions, etc for each sample, as well as expiration dates and positions of reagents. Reagent volumes are checked by the AQ700 to ensure there is sufficient volume on-board for all tests assigned.

Step 3

Reaction preparation begins

Using two sample arms and two high-precision syringes, the AQ700 aspirates and dispenses exact volumes of sample and reagent, dispensing into a dedicated reaction well for each sample test. The desired level of mixing occurs in the same reaction well. Any auto-dilutions assigned to samples are performed as the sample is dispensed into the reaction well - no additional sample cups or reaction wells are needed for assigned dilutions to take place.

Step 4

Incubation and color development

The reaction wells are heated to a set temperature, providing the necessary heat for some colorimetric reactions to take place as well as ensuring all reactions are temperature-controlled and equally treated. The reaction solution incubates for the programmed reaction time of the test as the sample arms continue preparing reactions.

Step 5

Aspiration and detection

As soon as the reaction solution completes its programmed reaction time, the aspiration probe transfers the solution out of the reaction well and into a 10 mm flow-through quartz cuvette using a peristaltic pump for steady intake. A lamp set inside of a rotating wavelength filter wheel is used to measure the absorbance of the reaction at the programmed wavelength. The absorbance is read and output to the system’s software where it is recorded and calculated as a concentration value.

Step 6

Cleaning of the quartz cuvette

The aspiration probe submerges in a wash bath and uses high-speed rinses of DI water and air to clean the quartz cuvette in preparation for the next reaction read.

Step 7

Dilution of over-range samples

If programmed, the system will dilute any over-range samples at the end of the run - using either a pre-programmed dilution factor or calculating the best dilution factor based on the sample’s absorbance. Over-range dilution sequences can be programmed to bracket with controls, ensuring quality assurance throughout the entirety of the run.

Step 8

Analyzing the next system tray

As soon as the run is complete, the AQ700’s robotic arm automatically moves the finished sample tray into the stand-by position and moves the next queued sample tray into the testing position and the analysis begins again. The finished sample tray can then be emptied, reloaded with samples, and added back into the testing queue for continuous operation.

Step 9

Review of data and export to LIMS

All sample results are displayed and fully observable as soon as the sample is analyzed. The analyst can review the completed data in the AQ software before exporting to LIMS. Export files are fully customizable ensuring integration with any LIMS program.

.jpg?resolution=1240x450&quality=95)

.jpg?resolution=1240x450&quality=95)

.jpg?resolution=1240x450&quality=95)

(1).jpg?resolution=1240x450&quality=95)

.jpg?resolution=1240x450&quality=95)

.jpg?resolution=1240x450&quality=95)

.jpg?resolution=1240x450&quality=95)

(1).jpg?resolution=1240x450&quality=95)

.jpg?resolution=1240x450&quality=95)

(1).jpg?resolution=1200x650&quality=95)

Software designed for chemists

Experience an intuitive software design for analyzer operation and streamlined data-handling. From import/export features for any LIMS, to a tab-based, familiar user-interface; our software is designed in-house for short learning curves, high functionality, and data integrity for regulated laboratories.

Discrete Analyzer Methods

Explore a wide range of our most common methods for environmental, agricultural, industrial, and other markets. Don’t see what you’re looking for? Contact our team to review our full method options.

| Analyte | Method Detection Limit | Equivalence |

| Alkalinity | 6.5 mg CaCO3/L (Range: 10 to 100 mg CaCO3/L) 8.0 mg CaCO3/L (Range: 15 to 200 mg CaCO3/L) 16 mg CaCO3/L (Range: 50 to 500 mg CaCO3/L) | EPA 310.2 (1974) |

| Ammonia (phenate reagent) | 0.004 mg N/L (Range: 0.02 - 2.0 mg N/L) 0.04 mg N/L (Range: 0.2 - 10 mg N/L) | EPA 350.1 (1993) SM 4500-NH3 F,G,H |

| Ammonia (phenate reagent, for brackish waters) | 0.07 mg N/L (Range: 0.2 to 5.0 mg N/L) | EPA 350.1 (1993) SM 4500-NH3 F,G,H |

| Ammonia (salicylate reagent) | 0.002 mg N/L (Range: 0.02 - 1.0 mg N/L) 0.005 mg N/L (Range: 0.1 - 5.0 mg N/L) 0.011 mg N/L (Range: 0.2 - 10 mg N/L) 0.18 mg N/L (Range: 1.0 - 100 mg N/L) | EPA 350.1 (1993) SM 4500-NH3 F,G,H |

| Chloride | 0.3 mg N/L (Range: 2.0 - 100 mg Cl/L) 0.4 mg N/L (Range: 5.0 - 200 mg Cl/L) | SM 4500-Cl E |

| Chromium, Hexavalent | 0.0005 mg Cr(VI)/L (Range: 0.003 - 0.5 mg Cr(VI)/L) 0.011 mg Cr(VI)/L (Range: 0.3 - 5.0 mg Cr(VI)/L) | SM 4500-Cr B |

| Color (480 nm) | 2 Color Units (Range: 5 - 150 Color Units) | SM 2120 B,C |

| Color (450 nm) | 2 Color Units (Range: 2 - 150 Color Units) | SM 2120 B,C |

| Cyanide, Total (Distillation Required) | 0.7 μg CN/L (Range: 2.0 – 250 μg CN/L) | EPA 335.4, Rev 1 (1993)SM 4500-CN E,N |

| Hardness, Total | 10 mg CaCO3 /L (Range: 25 – 400 mg CaCO3/L) | EPA 130.1 (1971) |

| Nitrogen, Total Kjeldahl (TKN, Cu Catalyst or Hg Catalyst Kjeldahl Digestion Required) | 0.04 mg N/L (Range: 0.25 – 10 mg N/L) 0.05 mg N/L (Range: 0.5 – 25 mg N/L) | EPA 351.2, Rev 2 (1993) SM 4500-Norg D |

| Nitrate + Nitrite (Cadmium Reduction, Ammonium Chloride Buffer) | 0.003 mg N/L (Range: 0.012 - 2.0 mg N/L) 0.007 mg N/L (Range: 0.04 - 5.0 mg N/L) 0.03 mg N/L (Range: 0.25 - 15 mg N/L) | EPA 353.2, Rev 2 (1993) SM 4500-NO3 E,F,I |

| Nitrate + Nitrite (Cadmium Reduction, Imidazole Buffer) | 0.004 mg N/L (Range: 0.012 - 2.0 mg N/L) | EPA 353.2, Rev 2 (1993) SM 4500-NO3 E,F,I |

| Nitrate + Nitrite (Hydrazine Reduction) | 0.005 mg N/L (Range: 0.02 - 1.5 mg N/L) 0.03 mg N/L (Range: 0.2 - 5.0 mg N/L) | EPA 353.1(1978) SM 4500-NO3 H |

| Nitrate + Nitrite (Vanadium (III) Chloride Reduction) | 0.004 mg N/L (Range: 0.025 - 1.0 mg N/L) | Easy (1-Reagent) Nitrate Method (2011) |

| Nitrite (with Buffer Addition) | 0.0001 mg N/L (Range: 0.0009 - 0.2 mg N/L) 0.0008 mg N/L (Range: 0.015 - 1.5 mg N/L) | EPA 353.2, Rev 2 (1993) SM 4500-NO3 E,F,I |

| Nitrite (no Buffer Addition) | 0.0002 mg N/L (Range: 0.001 - 0.2 mg N/L) 0.0005 mg N/L (Range: 0.015 - 1.5 mg N/L) | SM 4500-NO2 B |

| Phenolics (Distillation Required) | 0.002 mg Phenol/L (Range: 0.005 - 0.25 mg Phenol/L) | EPA 420.1 (1978) EPA 420.4, Rev 1 (1993) SM 5530 D |

| Phosphate, ortho | 0.0004 mg P/L (Range: 0.003 - 0.2 mg P/L) 0.0015 mg P/L (Range: 0.005 - 1.0 mg P/L) 0.005 mg P/L (Range: 0.05 - 5.0 mg P/L) 0.013 mg P/L (Range: 0.125 - 12.5 mg P/L) | EPA 365.1, Rev 2 (1993) EPA 365.3 (1978) SM 4500-P E,F,G,H |

| Phosphorus, Total (TP, Persulfate Digestion Required) | 0.003 mg P/L (Range: 0.01 - 1.0 mg P/L) 0.006 mg P/L (Range: 0.05 - 5.0 mg P/L) | EPA 365.1, Rev 2 (1993) EPA 365.3 (1978) SM 4500-P E,F,G,H |

| Phosphorus, Total Kjeldahl (TKP, Hg Catalyst Kjeldahl Digestion Required) | 0.007 mg P/L (Range: 0.04 - 3.2 mg P/L) | EPA 365.4 (1974) |

| Phosphorus, Total Kjeldahl (TKP, Cu Catalyst Kjeldahl Digestion Required) | 0.009 mg P/L (Range: 0.04 - 3.2 mg P/L) | EPA 365.4 (1974) |

| Silica (No Reduction) | 0.1 mg silica/L (Range: 0.25 - 25 mg silica/L) | SM 4500-SiO2 C |

| Silica (with ANSA Reduction) | 0.0042 mg silica/L (Range: 0.1 - 10 mg silica/L) | SM 4500-SiO2 D,E,F |

| Sulfate | 1.0 mg/L (5.0 - 40 mg/L) | ASTM D516-02,07,11,16 |

| Sulfate (use of gelatin as suspension agent) | 0.09 mg/L (5.0 - 40 mg/L) | ASTM D516-02,07,11,16 |

| Analyte | Method Detection Limit | Equivalence |

| Ammonia | 0.003 mg N/L (Range: 0.01 to 1.0 mg N/L) | ISO 7150-1 |

| Calcium | 0.23 mg/L (Range: 4 - 200 mg/L) | ISO 15923-2 |

| Chloride | 1.4 mg Cl/L (Range: 5 - 400 mg Cl/L) | ISO 15682 |

| Colour | 1 mg Pt/L (Range: 1 - 100 mg Pt/L) | ISO 7887:2011(E) |

| Fluoride | 0.022 mg F/L (Range: 0.08 - 2.5 mg F/L) 0.05 mg F/L (Range: 0.2 - 5.0 mg F/L) | ISO/DTA 15923-2 |

| Magnesium | 0.2 mg/L (Range: 0.4 - 20 mg/L) | ISO 15923-2 |

| Nitrate + Nitrite (Cadmium Reduction) | 0.01 mg N/L (Range: 0.1 - 6.0 mg N/L) | ISO/DIS 15923-1 |

| Nitrate + Nitrite (Hydrazine Reduction) | 0.0012 mg N/L (Range: 0.005 - 0.5 mg N/L) 0.008 mg N/L (Range: 0.1 - 6.0 mg N/L | ISO/DIS 15923-1 |

| Nitrite | 0.0003 mg N/L (Range: 0.02 - 1.0 mg N/L) | ISO/DIS 15923-1 |

| Phosphate | 0.002 mg P/L (Range: 0.006 - 1.0 mg P/L) | ISO 6878 |

| Silicate | 0.016 mg Si/L (Range: 0.05 - 6.0 mg Si/L) | ISO/DIS 15923-1 |

| Sulfate | 0.42 mg/L (Range: 4.0 - 200 mg/L) | ISO/DIS 15923-1 |

| Analyte | Extract | Method Detection Limit |

| Ammonia | 2 M KCl | 0.021 mg N/L (Range: 0.2 - 10 mg N/L) |

| Nitrate + Nitrite (Cadmium Reduction) | 2 M KCl | 0.015 mg N/L (Range: 0.06 - 5.0 mg N/L) 0.022 mg N/L (Range: 0.2 - 10 mg N/L) |

| Nitrate + Nitrite (Cadmium Reduction) | 0.1 M K2SO4 | 0.01 mg N/L (Range: 0.05 - 5.0 mg N/L) |

| Phosphate, available (P2O5) | Lancaster | 0.006 mg P/L (Range: 1.0 - 25 mg P/L) |

| Phosphate, ortho | Bray's P1 or P2, or similar extract | 0.015 mg P/L (Range: 0.05 - 5.0 mg P/L) |

| Phosphate, ortho | DI Water | 0.13 mg P2O5/L (Range: 7 - 350 mg P2O5) |

| Phosphate, ortho | Modified Morgan's or similar acetate/acetic acid extract | 0.01 mg P/L (Range: 0.2 - 8.0 mg P/L) |

| Phosphate, ortho | Olsen 0.5 M sodium bicarbonate extract | 0.01 mg P/L (Range: 0.1 - 5.0 mg P/L) |

| Phosphate, ortho | 2 M KCl | 0.04 mg P/L (Range: 0.1 - 5.0 mg P/L) |

| Phosphorus | Acetic acid | 0.5 mg P/L (Range: 10.0 - 1000 mg P/L) |

| Silica, available | Acetic acid | 0.25 mg SiO2/L (Range: 1.0 - 15 mg SiO2/L) |

| Sulfate | KH2PO4, or similar extraction | 0.75 mg SO4/L (Range: 5.0 - 40 mg SO4/L) |

| Analyte | Method Detection Limit | Range | Equivalence |

| Ammonia | 0.42 μM | 1.4 - 71 μM | EPA 350.1, Ver 2 (1993), SM 4500-NH3 G |

| Nitrite | 0.023 μM | 0.07 - 14 μM | EPA 353.2, Ver 2 (1993), SM 4500-NO2 B |

| Nitrate + Nitrite (Cadmium Reduction) | 0.125 μM | 0.71 – 71.4 μM | EPA 353.2, Ver 2 (1993), SM 4500-NO3 E,F,I |

| Phosphate, ortho | 0.015 μM | 0.1 – 7.0 μM | EPA 365.1, Ver 2 (1993), SM 4500-P F |

| Silica (Reactive Silica) | 0.011 mg silica/L | 0.1 – 10.0 mg silica/L | SM 4500-SiO2 D |

SEAL Discrete Analyzers in Peer-Reviewed Research

See how scientists worldwide utilize the SEAL AQ discrete analyzers in their research - from monitoring of water quality and agricultural run-off to soil fertility studies and more. Browse the curated publications and research articles below to see real-use cases for SEAL Analytical discrete analyzers.

Other models

Frequently Asked Questions

Below, we’ve listed a few frequently asked questions that will help you better understand our Discrete Analyzers. If you don’t find the answer you're looking for, please don't hesitate to contact our support team for further assistance.

SEAL Analytical’s AQ analyzers come standard with a 10 mm quartz flow-through cuvette used for all readings on the system. This material ensures the highest optical purity at detection. As the detector is entirely stationary rather than rotating to different wells, there is no added variance from changes in detector alignment. Additionally, each sample is analyzed in the same cuvette rather than individual wells, eliminating a critical variable in analysis conditions.

The traveling probe washer, unique to all SEAL discrete analyzers, ensures the sample probe is wiped clean and free of droplets before each sample probe movement. This ensures droplets are not falling off the sample probe into reaction wells, sample cups, reagent containers, etc as the sample probe moves to different locations. Additionally, it provides extra cleaning to the outside of the probe to further eliminate cross-contamination. The traveling probe washer is accompanied by a stationary wash bath for additional sample probe cleaning between crucial reaction steps.

Most carryover in discrete analysis happens during reaction preparation, but SEAL’s dual washing system described above eliminates this risk. At detection, high-speed water flushes alternating with air thoroughly clean the quartz cuvette, inspired by the proven rinsing method of our continuous flow analyzers.

Yes. Multiple parameters can be defined on the same samples, or different samples during the same run. This is all defined in the accompanying software that allows the analyst to define which parameters are analyzed on which samples.

AQ300: up to 97 sample positions; 18 reagent positions; 180 reaction positions

AQ400: up to 120 sample positions; 26 reagent positions; 216 reaction positions

AQ700: up to 424 sample positions, 24 reagent positions; 848 reaction positions

Yes, all AQ discrete analyzers are equipped with the ability to run Nitrate+Nitrite by cadmium reduction, in addition to other common reduction pathways including hydrazine sulfate, vanadium (III) chloride, and enzymatic reduction. A tubular cadmium coil is fitted in a dedicated loop so only sample and buffer pass through the cadmium coil during the reduction step of a Nitrate+Nitrite test. All other tests bypass the cadmium coil so that the cadmium coil can always be installed on the system.

Yes, all SEAL discrete analyzers offer auto-dilution capabilities. Dilutions can be assigned to samples before the run for the analyzer to dilute the samples immediately before analysis. As an additional option, over-range samples can be flagged by the software for auto-dilution at the end of the run. The software allows for dilution factors and post-run quality control bracketing for dilutions to be customizable by test, ensuring you meet your compliance requirements.

Latest news

Need support? We are here to help

Request Information

Fill out the form below to request information about our products and services.

(1).jpg?resolution=1200x650&quality=95)

(7).png?resolution=290x200&quality=95)

.png?resolution=290x200&quality=95)

.png?resolution=290x200&quality=95)

.jpg?resolution=428x267&quality=95)

.png?resolution=428x267&quality=95)