MiniLab Biochemical Oxygen Demand

Robotic precision and flexibility for reliable automated BOD analysis.

Product Overview

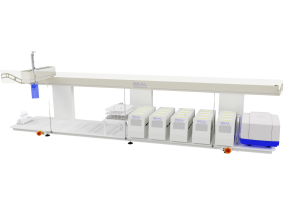

SEAL Analytical’s MiniLab BOD series can automate every aspect of biochemical oxygen demand (BOD) pre-treatment and analysis through streamlined software configuration and minimal user interaction. Precision robotics efficiently replicate traditional manual methods with speed, accuracy, and consistency, handling preparation steps like pH adjustment, chemical and seed additions, dilutions, and more. Simply add the samples and walk away with full confidence that the MiniLab will take care of it all.

The MiniLab BOD is available in a variety of footprint sizes to suit your space and capacity requirements.

Discover SEAL Automation for BOD

Explore our BOD Robotics RangeWhy select the MiniLab BOD?

Automation

- Seamless sample additions for 24/7 continuous operation and analysis

- Sample prep including barcode scanning, conductivity, pH read & adjustment, homogenization, air purging, and pre-dilutions

- BOD analysis including capping/decapping, dosing sample, addition of dilution water, ATU, and seed, and DO reading

Compliance

- Precise, repeatable results free of human error

- Fully audited sample management ensures total compliance with regulatory standards

- Exportable results

- Uses standard BOD bottles

- Optional temperature-controlled enclosure

Efficiency

- High throughput with multi-probe, multi-dispense options

- Improved repeatability and reproducibility

- Reduce lab process cycle times

- High analytical capacity: from 15 to 300 samples per system (application and model dependent)

- Free staff from repetitive, time-consuming manual tasks

Support

- Visual manuals and descriptive checklists

- Immediate support available from SEAL chemists via email, phone, screenshare, or video call

- In-depth training during installation

- Guides and webinars available for continued learning

MiniLab BOD Highlights

.png?resolution=595x500&quality=95)

.jpg?resolution=595x500&quality=95)

.png?resolution=595x500&quality=95)

(1).png?resolution=595x500&quality=95)

.jpg?resolution=595x500&quality=95)

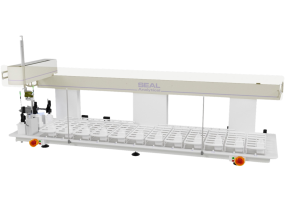

Experience trouble-free mechanical operation with SEAL’s signature encoded motors on the MiniLab ML platform. These motors provide real-time feedback and precision control to the system, ensuring greater accuracy in movement and positioning.

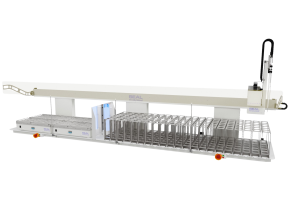

The SEAL MiniLab Series offers a scalable approach to laboratory automation in both system size and automation level.

From a single-armed MiniLab AR2 (seen on upper-right) to a multi-armed MiniLab ML4000 (seen on bottom), or something in-between, SEAL offers a system to meet your throughput, capacity, and budgetary needs.

The level of automation and throughput in your MiniLab system can be configured to meet your individual needs. Choose your automation steps including sample dosing & diluting, addition of dilution water/seed/ATU, mixing, DO read, capping/decapping and more!

Automate your processes even further with sample prep modules, including barcode reading, conductivity reading, pH reading & adjusting, homogenizing with Ultra Turrax, air purging, and more!

Discover hassle-free DO readings with optical probes, eliminating the maintenance requirements of membrane probes. Employ up to six probes per arm for incredible throughput rates.

(3).jpg?resolution=1200x650&quality=95)

Reduced Bottle Hassle with Environmental Express®

SEAL's MiniLab platforms are designed to work with both traditional glass BOD bottles as well as Environmental Express Eco-Conscious Single-Use BOD Bottles. These bottles are lightweight, unbreakable, and recyclable, offering convenience while reducing labor costs. With a specialized carbon coating to prevent oxygen diffusion, individually numbered bottles arrive pre-cleaned and ready for use, ensuring more accurate BOD results.

How the MiniLab BOD Works

Step 1

BOD Bottles are placed on MiniLab platform

An analyst prepares samples for BOD testing and dispenses into BOD bottles loaded onto the MiniLab trays. The trays are then placed on the MiniLab platform.

Alternatively, the MiniLab can also prepare samples: capping/decapping air purging, reading conductivity and pH, adjusting pH, homogenizing, and performing dilutions while transferring to BOD bottles.

Step 2

Worklist created in the BOD Software

Using SEAL’s BOD software, the analyst assigns positions and enters sample data into the software, or imports a work list from the LIMS.

Alternatively, the MiniLab can create work tables automatically using onboard barcode scanning.

Step 3

Analysis begins

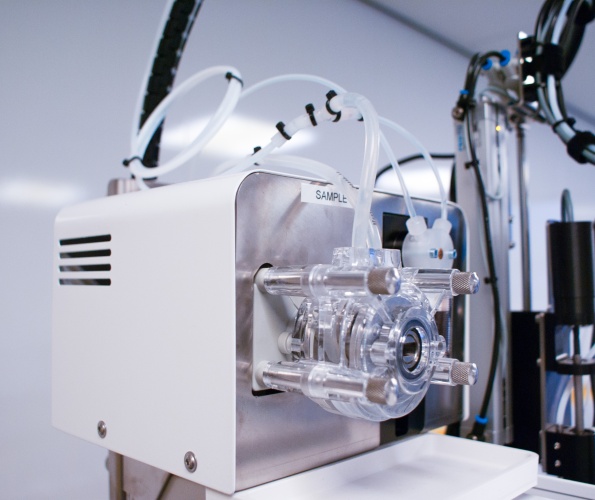

Once the run is started, the MiniLab begins dispensing dilution water into the first two sample bottles using a calibrated peristaltic pump. While mixing, seed and ATU (if needed) are also added.

Step 4

Initial Dissolved Oxygen Read

Initial DO takes place via optical probes as the next two BOD bottles are prepared. This process continues until all bottles assigned have been filled and analyzed.

Step 5

Bottle incubation

Once the run is complete, the analyst stores the BOD trays in an incubator for required incubation time.

Step 6

Final Dissolved Oxygen Read

When the incubation is complete, the analyst places the BOD trays back on the MiniLab. The same run is opened in the BOD software and final dissolved oxygen reads take place.

Step 7

Data exported to LIMS

After the run is completed, sample data is exported to LIMS for further analysis and record keeping.

Note: Additional steps, such as decapping and capping bottles, may be required depending on the specific automation add-ons integrated into your robotic handling system.

.jpg?resolution=1240x450&quality=95)

(2).jpg?resolution=1200x650&quality=95)

Intuitive software for a tailored experience

SEAL’s intuitive BOD Analyzer software simplifies tracking and controls every step of the prep and analysis process. It offers real-time visualization of the run status, easy integration with your LIMS, and detailed reporting and tracking of all sample data. You have the flexibility to personalize aspects of the process, including the number of measurements, readings, stirring delays, measurement delay times, rinses, and more, allowing you to create methods that meet your specific laboratory requirements.

Available features and capabilities of the software will vary depending on the automation options selected for the MiniLab robotic handling system.

BOD Methods

Explore a wide range of our most common methods for environmental, agricultural, industrial, and other markets. Don’t see what you’re looking for? Contact our team to review our full method options.

Scope and Application

This method covers the determination of Dissolved Oxygen in wastewater samples.

| Applicable Range | 0.5 – 20.0 mg/L ± 0.1 mg/L |

This method is equivalent to Standard Method 5210 B, ASTM D888, EPA 405.1, ISO 1899-1, 1899-2 and ISO 5815-1.

Method Description

Biochemical Oxygen Demand (BOD) measures the depletion of oxygen over a five-day period. The process involves reading the sample at day zero (initial DO reading) and at day five (final DO reading), then subtracting to determine the oxygen depletion caused by microorganisms present in the sample.

Optical probes are commonly used, though membrane probes are also available.

Other models

Frequently Asked Questions

Below, we’ve listed a few frequently asked questions that will help you better understand our MiniLab Series. If you don’t find the answer you're looking for, please don't hesitate to contact our support team for further assistance.

Yes, the MiniLab software includes seamless import functionality from LIMS. You can create an import file in LIMS to transfer specific data into the MiniLab software. The data fields to be imported can be defined via Settings > Import Settings.

The MiniLab software also includes data export functionality to transfer data and results back to LIMS. Use the Export Settings to define the format of the export file.

Yes, the MiniLab BOD Prep supports various sample pre-treatment tasks, including barcode scanning, conductivity reading, sample homogenization, air purging, and capping/decapping. It also allows for pH neutralization by automatically adding acid or base, providing an automated solution for BOD sample preparation.

It is recommended to use tap water or a salt solution as the dilution liquid in the MiniLab BOD. This is because the filling method operates based on electrical conductivity: at the final filling level, two metal pins are positioned. When current is detected between these pins, the addition of dilution water stops automatically.

The MiniLab BOD focuses solely on BOD testing, delivering accurate and reliable measurements.

The MiniLab BOD Prep, on the other hand, offers a complete automated solution by combining BOD testing with advanced sample pre-treatment capabilities. It includes features such as barcode scanning, conductivity reading, sample homogenization, air purging, capping/decapping, and automatic pH neutralization, making it ideal for streamlined and automated sample preparation.

We offer multiple options with our customizable platforms, ranging from just a few to hundreds, depending on your workload. We will match your requirements and recommend the best option to maximize your lab's efficiency.

We offer multiple options with our customizable platforms. From a few to hundreds, depending on your workload. We will match your requirement and recommend the best option to maximize your lab's efficiency.

Need support? We are here to help

Request Information

Fill out the form below to request information about our products and services.

.png?resolution=290x200&quality=95)