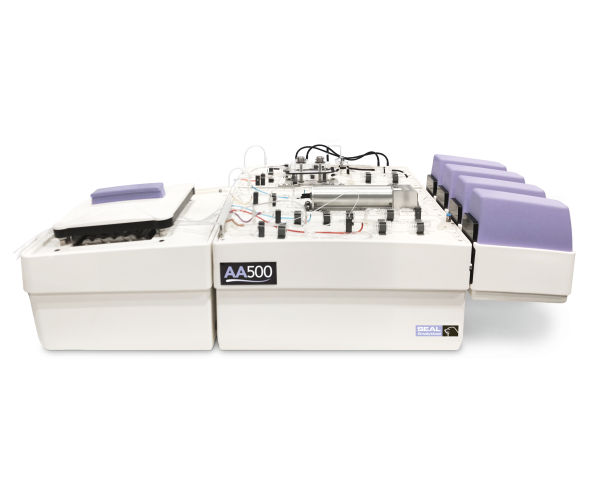

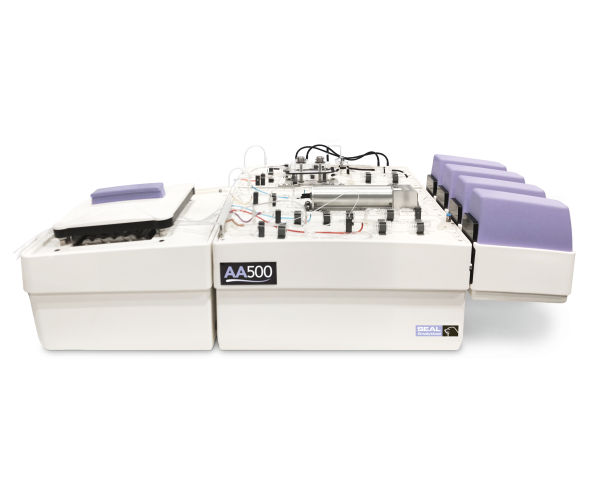

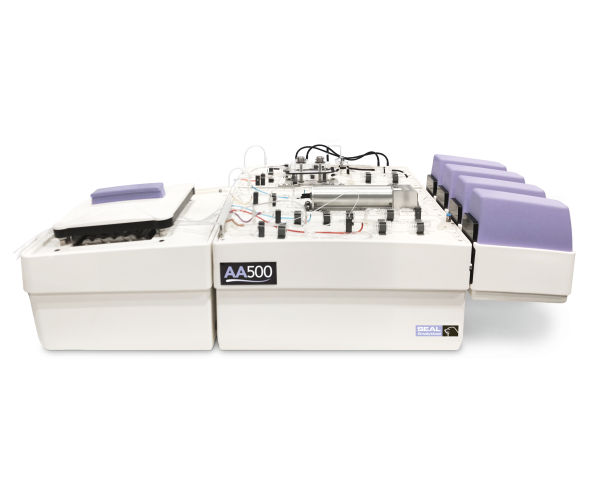

Feature-Packed Automated Analysis

The AA500 is the next step in the evolution of the original world-class Technicon AutoAnalyzer, following the SEAL Analytical AA3 segmented flow analyzer. With compact, all-in-one housing, the system delivers up to six channels with total automation of startup and shutdown, as well as full digital control of digestion, distillation, and air injection. Focused on maintaining the AutoAnalyzer’s long standing reputation for high quality and reliability, the AA500 brings unequaled performance, flexibility and productivity enhancements to the laboratory.

The AA500 incorporates the same principles employed in a basic segmented flow analyzer (SFA) system: an autosampler, a peristaltic pump, a chemistry manifold,a detector and data acquisition software. Sample and reagents are pumped continuously through the chemistry manifold. Air bubbles are introduced at regular intervals forming unique reaction segments which are mixed using glass coils. Glass is ideal as it is inert, stays clean and enables easy visual checks.

In SFA, reactions run to completion and the ratio of sample to reagents in the detector reaches a constant, stable value. This results in ultra-low detection limits and exceptional reproducibility. Variations in reaction time, temperature and sample matrix do not affect the results as they do in other colorimetric techniques, such as flow injection analysis, where the reaction is not brought to completion.

The AA500 is the top-of-the line AutoAnalyzer incorporating the latest innovations to deliver your laboratory the freedom of total automation while achieving very high precision and the lowest detections levels. It is the AutoAnalyzer you’ve been waiting for.

View the full specifications

Download the brochureWhy select the AA500?

Automation

- Programmable steps for a fully automated startup and shutdown, including platen release

- SEAL Sampler series designed and manufactured by SEAL Analytical for improved segmented flow analysis sampling

- Inline sample pretreatment including distillation, gas diffusion, dialysis, dilution, and UV digestion

- 6+ channels for simultaneous analyses

Compliance

- Segmented reaction stream allows for a complete reaction between reagents and sample for maximum sensitivity

- Over 1,000 methods available

- LIMS-compatible software available in standard and GLP versions

- Wide-range methods allow for more testing without dilution reruns

Efficiency

- Modular, small footprint components for a flexible, space-saving flow analyzer

- Dual-beam LED photometer provides ultra-low detection with a long life and low maintenance

- Inert glass tubing for accurate results and easy maintenance

- Multitest manifolds enable analysis of multiple parameters on a single channel, requiring only reagent and LED changes between tests

Support

- Visual manuals and descriptive checklists

- Immediate support available from SEAL chemists via email, phone, screenshare, or video call

- In-depth training during installation

- Guides and webinars available for continued learning

Highlights of the AA500

.jpg?resolution=595x500&quality=95)

.jpg?resolution=595x500&quality=95)

Utilizing segmented flow analysis, SEAL flow analyzers use less reagent than other variations of continuous flow analysis. Segmented flow also brings the reaction to reach complete color formation, allowing the signal to reach a steady state for precise measurement.

Utilizing high resolution dual beam LED digital photometers and unique flowcell engineering, the AA500 provides incredibly low detection limits, well-suited for seawater research and other low-level applications.

SEAL’s multi-test manifolds allow for a single AA500 channel to be used for multiple parameters. The same glassware and pump tube configurations remain in place between methods - simply pump rinse solution through the channel and swap out the detector’s LED to the desired wavelength. A single manifold also allows for multiple ranges depending on the current need.

The AA500 offers a fully automated startup and shutdown, customizable by the user via programmable steps in the AACE software ensuring a safe and efficient shutdown on every run. Setup a run for overnight analysis and let the system dilute and rerun over-range samples, rinse out the channels with wash solution, and release the pump platen entirely unattended.

How the AA500 Works

Step 1

Startup and Baselines

Using programmable auto-startup options or manual steps, the system is powered on and wash solution is pumped through the system. After the baseline has stabilized, reagents are introduced through the pump tubing via automatic valves or manually. A stable baseline is achieved before analysis begins.

Step 2

Samples are loaded and scheduled

A sample list or sequence is entered into the software, either imported directly from LIMS or a spreadsheet, or entered manually. If using a syringe diluter, auto-dilution factors are assigned. Samples are loaded onto the sampler.

Step 3

Sampling begins

Once the run is started, the standards and samples are pulled sequentially through the sample probe by the peristaltic pump and flow-rated pump tubes. The sampler returns to the wash bath between samples for cleaning, separating sample and wash solution with an air bubble to minimize dispersion and reduce carryover. The sample is split into multiple channels as it approaches the pump for simultaneous analysis of various analytes. As the sample enters the manifold, an air bubble is injected at regular intervals to provide additional separation between samples.

Step 4

Reaction underway

As the samples pass through the manifold, precise volumes of reagents are injected at specific points, pulled through the peristaltic pump by their own flow-rated pump tubes. The reaction solution passes through a range of apparatuses such as mixing coils, heating baths, dialyzers, gas diffusion blocks, UV digestors, and more to facilitate the colorimetric reaction.

Step 5

Detection takes place

The reaction solution reaches peak color development before passing into the flowcell. Using a dual beam LED digital photometer, constant absorbance readings of the flow are measured and plotted on a chart in the AACE software in real time. As the colored reaction solution enters and leaves the detector, peaks are formed on the chart. Peak height is then measured and compared to the calibration to calculate a concentration value of the sample.

Step 6

Post-run dilutions and shutdown

After the run completes, over-range samples can be automatically diluted using a syringe diluter and reanalyzed if desired. At the end of analysis, a programmable auto-shutdown program can be used to automatically rinse out the channels, raise the peristaltic pump’s platen to prevent damage to the flow-rated pump tubes, turn off LED lamps, turn off heating baths, and other shutdown procedures.

(1).jpg?resolution=1200x650&quality=95)

Powerful AACE Software

The AACE software package for the AA500 allows for full digital control of all the analyzer’s functions. Designed in-house at SEAL Analytical, AACE is compatible with Windows 7 - 11 and offers regular updates keeping up with new operating systems. Offering LIMS import and export compatibility and GLP-compliance, AACE is compatible with all laboratories' data-handling needs.

AA500 AutoAnalyzer Methods

Explore a wide range of our most common multi-test methods for environmental, agricultural, industrial, and other markets. Multi-test manifolds allow for a single channel to be used for any parameter on the same multi-test list, without any pump tubing, glassware, or manifold changes. Don’t see what you’re looking for? Contact our team to discuss our full method options, including methods with gas diffusion, UV digestion, fluorometry, and more.

SEAL Analytical has more than 1,000 documented segmented flow analyzer methods, with new applications regularly being developed in our laboratories. USEPA, ASTM, ISO, AOAC, DIN, CORESTA and other international regulatory compliant methods are available.

| Analyte | SEAL Method # | Lowest Range | Highest Range |

| Alkalinity | A097 | 0 – 250 mg/L as CaCO3 | 0 – 500 mg/L as CaCO3 |

| Aluminium | A137 | 0- 200 µg/L as Al | 0 - 600 µg/L as Al |

| Aluminium | A141 | 0 - 1 mg/L as Al | 0 - 4 mg/L as Al |

| Ammonia (Phenol reagent) | A025 | 0 - 2.5 mg/L as N | 0 - 25 mg/L as N |

| Ammonia (Salicylate reagent) | A041 | 0 - 3 mg/L as N | 0 - 25 mg/L as N |

| Ammonia (ISO chemistry) | A042 | 0 - 3 mg/L as N | 0 - 30 mg/L as N |

| Ammonia (for soil extracts) | A048 | 0 - 3 mg/L as N | 0 - 25 mg/L as N |

| Boron | A134 | 0 - 10 mg/L as B | 0 - 90 mg/L as B |

| Calcium | A083 | 0 - 15 mg/L | 0 - 100 mg/L |

| Chloride | A085 | 0 - 25 mg/L | 0 - 700 mg/L |

| Chromium (VI) | A090 | 0 - 4 mg/L as Cr | 0 - 40 mg/L as Cr |

| Hardness | A084 | 0 - 400 mg/L as CaCO3 | 0 - 400 mg/L as CaCO3 |

| Hydrogen Sulfide | A096 | 0 - 4.5 mg/L as S | 0 - 18 mg/L as S |

| Magnesium | A099 | 0 - 4.5 mg/L as S | 0 - 18 mg/L as S |

| Nitrate | A026 | 0 - 1 mg/L as N | 0 - 12 mg/L as N |

| Nitrate | A068 | 0 - 1 mg/L as N | 0 - 10 mg/L as N |

| Nitrite | A047 | 0 - 2 mg/L as N | 0 - 8 mg/L as N |

| Nitrogen, total Kjeldahl | A066 | 0 - 2.5 mg/L as N | 0 - 25 mg/L as N |

| Phosphate | A029 | 0 - 10 mg/L as P | 0 - 50 mg/L as P |

| Phosphorus, total Kjeldahl | A067 | 0 - 6 mg/L as P | 0 - 50 mg/L as P |

| Silicate | A030 | 0 - 30 mg/L as SiO2 | 0 - 300 mg/L as SiO2 |

| Analyte | SEAL Method # | Lowest Range | Highest Range |

| Alkalinity | A097 | 0 – 250 mg/L as CaCO3 | 0 – 500 mg/L as CaCO3 |

| Aluminium | A137 | 0- 200 µg/L as Al | 0 - 600 µg/L as Al |

| Aluminium | A141 | 0 - 1 mg/L as Al | 0 - 4 mg/L as Al |

| Ammonia (Phenol reagent) | A025 | 0 - 0.5 mg/L as N | 0 - 6 mg/L as N |

| Ammonia (Salicylate reagent) | A041 | 0 - 0.8 mg/L as N | 0 - 6.4 mg/L |

| Ammonia (ISO chemistry) | A042 | 0 - 1 mg/L as N | 0 - 8 mg/L as N |

| Boron | A134 | 0 - 2 mg/L as B | 0 - 15 mg/L as B |

| Chloride | A085 | 0 - 10 mg/L | 0 - 300 mg/L |

| Chromium (VI) | A090 | 0 - 1 mg/L as Cr | 0 - 9 mg/L as Cr |

| Chromium (VI) | A131 | 0 - 1 mg/L as Cr | 0 - 9 mg/L as Cr |

| Hydrogen Sulfide | A096 | 0 - 0.75 mg/L as S | 0 - 1.8 mg/L |

| Magnesium | A099 | 0 - 0.75 mg/L as S | 0 - 1.8 mg/L |

| Nitrate | A026 | 0 - 240 µg/L as N | 0 - 2.8 mg/L as N |

| Nitrite | A047 | 0 - 0.2 mg/L as N | 0 - 0.8 mg/L as N |

| Nitrogen, total Kjeldahl | A066 | 0 - 0.8 mg/L as N | 0 - 25 mg/L as N |

| Phosphate | A029 | 0 - 1 mg/L as P | 0 - 8 mg/L as P |

| Phosphorus, total Kjeldahl | A067 | 0 - 1.7 mg/L as P | 0 - 8 mg/L as P |

| Silicate | A030 | 0 - 6 mg/L as SiO2 | 0 - 60 mg/L as SiO2 |

| Analyte | SEAL Method # | Lowest Range | Highest Range |

| Alkalinity | A088 | 0 - 100 mg/L as CaCO3 | 0 - 250 mg/L as CaCO3 |

| Ammonia | A032 | 0 - 0.5 mg N/L | 0 - 5 mg/L as N |

| Nitrate+Nitrite | A033 | 0 - 200 µg N/L | 0 - 2 mg/L as N |

| Nitrite | A035 | 0 - 0.2 mg N/L | 0 - 2 mg/L as N |

| Phosphate | A036 | 0 - 1 mg P/L | 0 - 5 mg/L as P |

| Total Kjeldahl Nitrogen | US310 | 0 - 0.5 mg N/L | 4 mg/L as N |

| Total Kjeldahl Phosphorus | A073 | 0 - 1.5 mg P/L | 0 - 5 mg/L as P |

| Analyte | SEAL Method # | Lowest Range | Highest Range |

| Total Nitrogen (Cadmium coil reduction) | A076 | 10 - 500 μg/L as N | 0.1 – 5 mg/L as N |

| Total Nitrogen (Hydrazine reduction) | A077 | 0 - 0.75 mg/L as N | 0 - 5 mg/L as N |

| Total Phosphorus | A078 | 0- 3 mg/L as P | 0 - 10 mg/L as P |

| Total Nitrogen (Cadmium column reduction) | A118 | 10 - 500 μg/L as N | 0.1 – 5 mg/L as N |

| Analyte | SEAL Method # | Lowest Range | Highest Range |

| Ammonia (Phenol Reagent) | A001 | 0 – 8 μmol/L | 0 – 100 μmol/L |

| Ammonia (Salicylate Reagent) | A043 | 0 - 8 μmol/L | 0 - 1350 μmol/L |

| Chloride | A145 | 0 - 6 mg Cl/L | 0 – 400.0 mg/L |

| Color | A109 | 0 - 70 color units | 0 - 250 color units |

| Iron | A155 | 0 - 2 µmol/L | 0 - 80 µmol/L |

| Manganese | A123 | 0 - 300 µg/L | 0 - 7.5 mg/L |

| Nitrite | A044 | 0 - 3.6 µmol/L | 0 - 500 µmol/L |

| Nitrate+Nitrite | A044 | 0 - 3.6 µmol/L | 0 - 500 µmol/L |

| Phosphate | A005 | 0 - 2 μmol/L | 0 - 64.5 μmol/L |

| Silicate | A006 | 0 - 8 µmol/L | 0 - 1 mmol/L |

| Total Kjeldahl Nitrogen | A124 | 0 - 160 µmol/L | 0 - 1200 µmol/L |

| Total Nitrogen | A063 | 0 - 1 mg N/L | 0 - 12 mg N/L |

| Total Phosphorus | USA002 | 0 - 1 mg P/L | 0 - 1 mg P/L |

| Analyte | SEAL Method # | Lowest Range | Highest Range |

| Cyanide | A116 | 0 - 25 µg/L as CN | 0 - 500 µg/L as CN |

| Cyanide, free | A144 | 0 - 50 µg/L as CN | 0 - 500 µg/L as CN |

| Phenol | A117 | 0 - 200 µg/L | 0 - 500 µg/L |

| Analyte | SEAL Method # | Lowest Range | Highest Range |

| Nitrogen, total dissolved (Cadmium column reduction) | A008 | 0 - 10 μmol/L | 0 - 40 μmol/L |

| Nitrogen, total dissolved (Cadmium coil reduction) | A110 | 0 - 10 μmol/L | 0 - 40 μmol/L |

| Phosphorus, total dissolved | A009 | 0 - 5 μmol/L | 0 - 50 μmol/L |

| Analyte | SEAL Method # | Lowest Range | Highest Range |

| Iron, total | A114 | 0 - 300 µg/L | 0 - 3 mg/L |

| Copper, total | A115 | 0 - 100 µg/L | 0 - 300 µg/L |

AutoAnalyzers in Peer-Reviewed Research

See how scientists worldwide utilize the SEAL Analytical AA500 and other AutoAnalyzer models in their research - from water quality monitoring and seawater nutrient detection to soil fertility studies and more. Browse the curated publications and research articles below to see real-use cases for SEAL Analytical AutoAnalyzers.

Other models

Frequently Asked Questions

Below, we’ve listed a few frequently asked questions that will help you better understand our Continuous Flow Analyzers. If you don’t find the answer you're looking for, please don't hesitate to contact our support team for further assistance.

The AA500 comes integrated with a software-controlled pump platen, programmable reagent valves, and other automated components. Custom start-up and shut-down programs can be created in the software to fully customize your automated analysis. With the click of a button, the analyzer can engage its platen, begin pumping wash solution through the system, and turn on heating baths and lamps. It can then automatically begin pumping reagents in the proper reagent order, engage the cadmium reduction valve if needed, wait for and identify a stable reagent baseline, and then begin the run. At the end of the run, it can automatically dilute and reanalyzer over-range samples, then disengage the cadmium reduction valve if needed, switch over from reagents to wash solution in the proper order, switch the pump to a fast speed for expedited rinsing, shut off heating baths and LED lamps, release the platen, and raise the sample probe out of the wash bath.

Our continuous flow analyzers can analyze samples at up to 120 samples/hour per channel, for a total of up to 600 tests per hour.

Our continuous flow analyzers utilize segmented flow analysis, injecting controlled bubbles at a regular interval which provides several benefits. The bubbles reduce carryover by adding physical separation between sample and wash solution, they improve the mixing of sample and reagent in-between air bubbles, they scrub the inner surface of the glass coils as the move along, and they provide a visual of the flow through the system for easy fluidic checks.

Segmented flow analysis and flow injection analysis are both types of continuous flow analysis. In segmented flow analysis, a gas bubble is injected into the sample stream at regular intervals (see question above). In flow injection analysis, samples an reagents are pumped into a manifold under pressure without any air bubble injection. Each type of continuous flow analysis uses different methods for analyzing the peaks charted as samples pass through the detector. We discuss these differences in detail here.

With minimal moving parts, segmented flow analysis has an advantage in requiring little routine maintenance. The maintenance involved includes rinsing out the channels after each run using the defined cleaning protocols for the chemistry ran on the instrument, releasing the platen so the pump tubes are not compressed when not in use, changing the flow-rated pump tubes at 200 hours of use, and keeping the pump clean and lubricated. Each SEAL analyzer comes with checklists and visual guides for these easy procedures, and our technical support team is always happy to assist with any questions.

Related articles

Need support? We are here to help

Request Information

Fill out the form below to request information about our products and services.

.jpg?resolution=290x200&quality=95)

.png?resolution=290x200&quality=95)

.jpg?resolution=428x267&quality=95)

.png?resolution=428x267&quality=95)